Funding supports solution to detect lead in drinking water

Research led by Mark Burns is refining a solution to rapidly detect lead in drinking water.

Research led by Mark Burns is refining a solution to rapidly detect lead in drinking water.

Research led by Mark Burns, T.C. Chang Professor of Engineering, recently received funding from Helen of Troy Limited to refine a solution to rapidly detect lead in drinking water.

High levels of lead contamination in drinking water can pose severe health risks to humans, including slowing growth and development in children and causing damage to the nervous system.

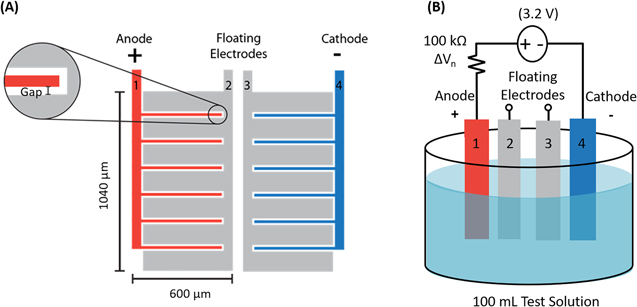

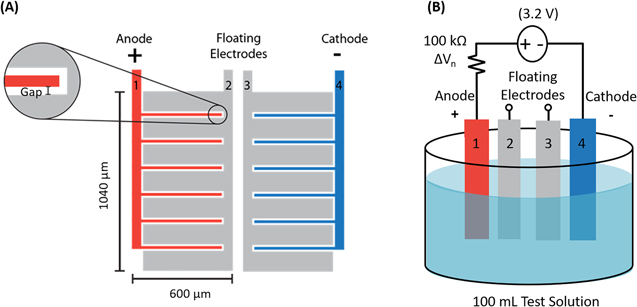

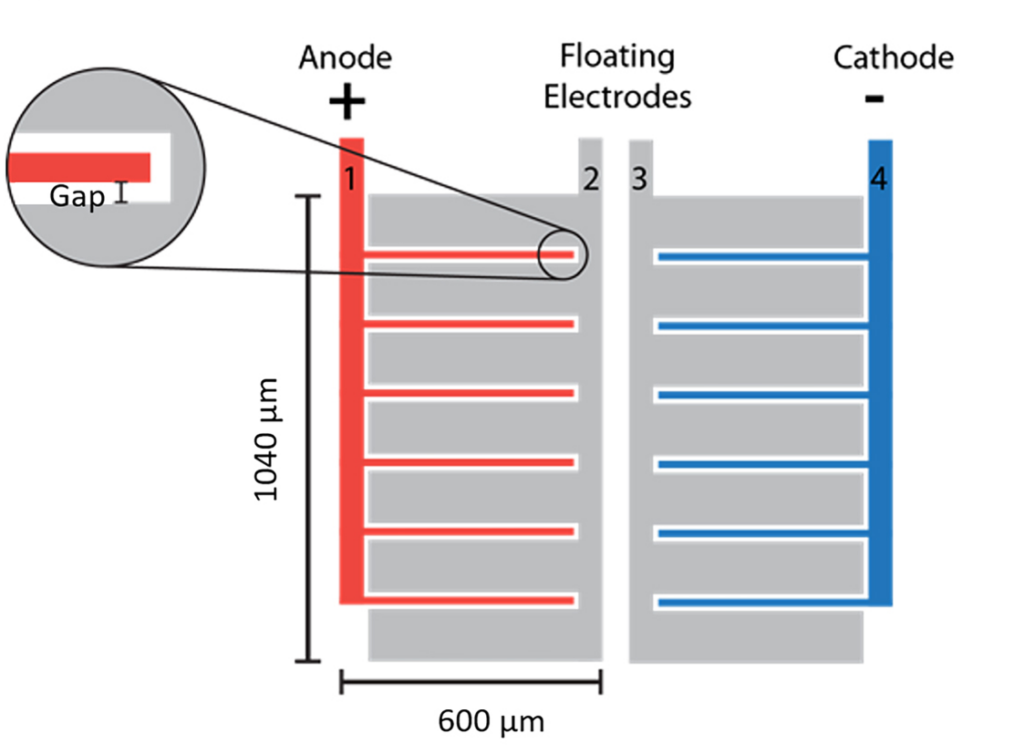

During previously funded work, the Burns lab designed, fabricated and optimized an interdigitated four-electrode lead sensor that can accurately and reliably signal high lead levels in drinking water. The sensor is comprised of an anode and its neutral floating electrode and a cathode and its neutral floating electrode.

Lead detection takes place in water when the gap between the anode and its neutral floating electrode is bridged by lead oxide deposition. Using this method, the deposition of lead oxide can take several days to trigger a response. The Burns lab and collaborators have been able to successfully shorten the detection time by 40% using the new design.

“The goal is a practical device for the detection of lead in drinking water, which would enable us to prevent harmful lead exposure,” said Brian Johnson, lead engineer in research. “This funding will allow us to continue producing these devices.”

“The goal is a practical device for the detection of lead in drinking water, which would enable us to prevent harmful lead exposure.”

Brian Johnson

Biochemical Microsystems Research Engineer

Currently, the Burns team is supplying sensors to collaborators at the Helen of Troy Limited, with a goal of integrating them within their sensing device and testing them in the field. Additionally, Burns’ team is looking into new designs to further improve lead sensor performance.

With minor improvements, the portable and user-friendly sensors could easily be deployed in a variety of water infrastructure locations, including residential homes, to prevent the consumption of lead.

“We are excited that Helen of Troy is continuing to work with us in developing this sensor,” Johnson said.

The Burns Research Group is constructing miniaturized chemical analysis systems, like this sensor, using silicon microfabrication techniques. Other devices consist of micron-scale reaction, separation and detection systems connected by a series of micromachined channels.

Additional collaborators include Postdoctoral Research Fellow Sanaz Habibi, recent Chemical Engineering PhD graduate Anna Nelson, Jae Sung Lee and Wen-Chi Lin.