A stretchable nano-crumpled material could help prevent infection in patients with medical implants

The material could provide a low-cost and scalable solution for long-term antibacterial protection.

The material could provide a low-cost and scalable solution for long-term antibacterial protection.

Infections can be a big problem for patients with medical implants, but there might be a solution that is both affordable and effective. A team of researchers including Chemical Engineering Assistant Professor, Jouha Min have developed a way to coat medical implants with special materials that can remove and prevent bacterial infections.

When patients have medical implants like artificial joints or pacemakers, infections can occur and cause complications. Infections can cause implants to stop working, damage the tissue around them and sometimes even lead to amputation.

To address this issue, Min and collaborators have created a unique coating method for medical implants that is easy to manufacture and possesses long-lasting antibacterial properties. Recently published in Advanced Materials Interfaces, the research outlines a nanofabrication approach for producing a durable coating for medical implants.

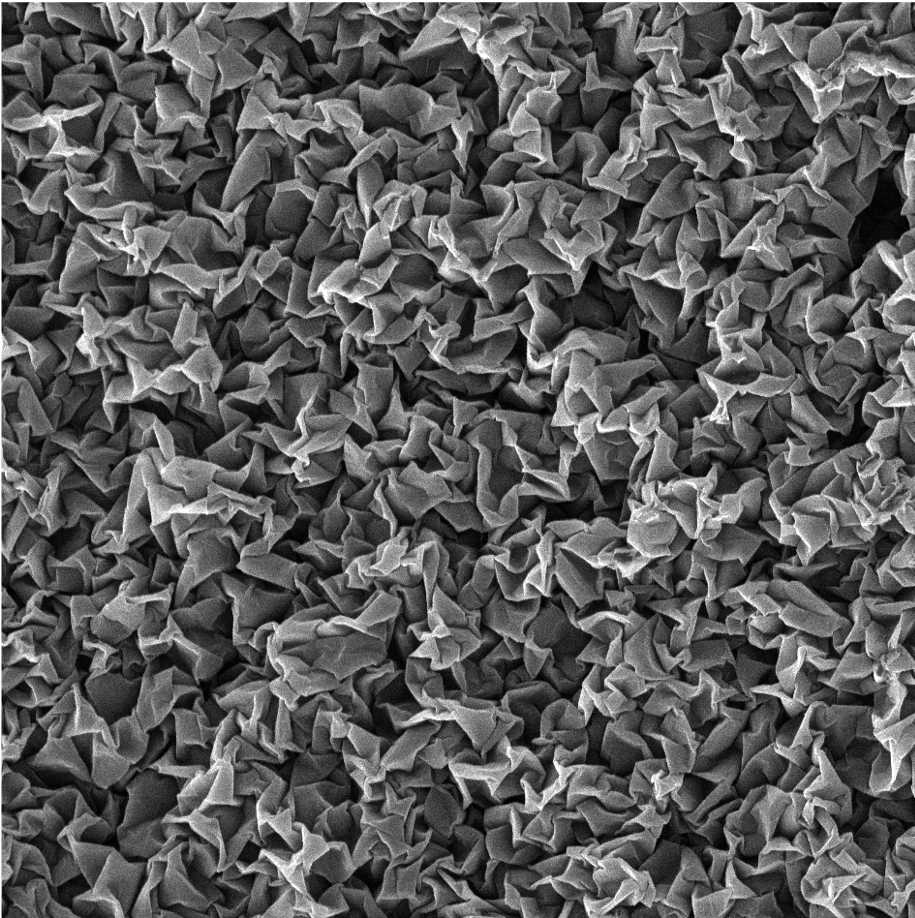

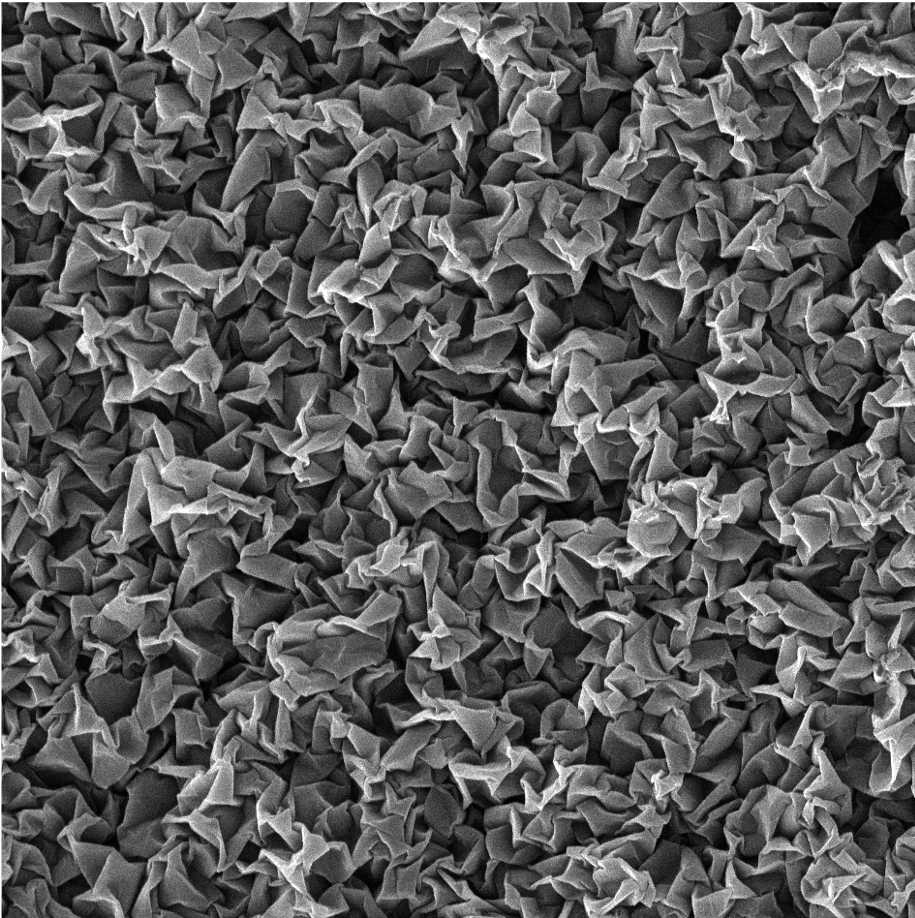

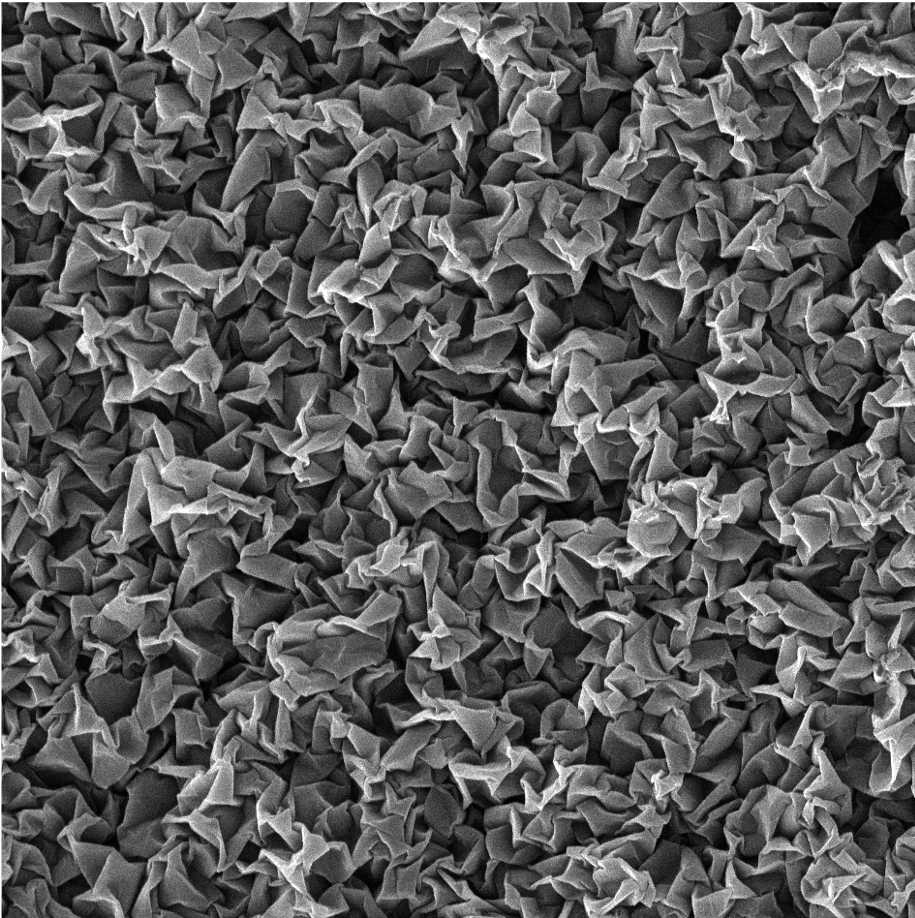

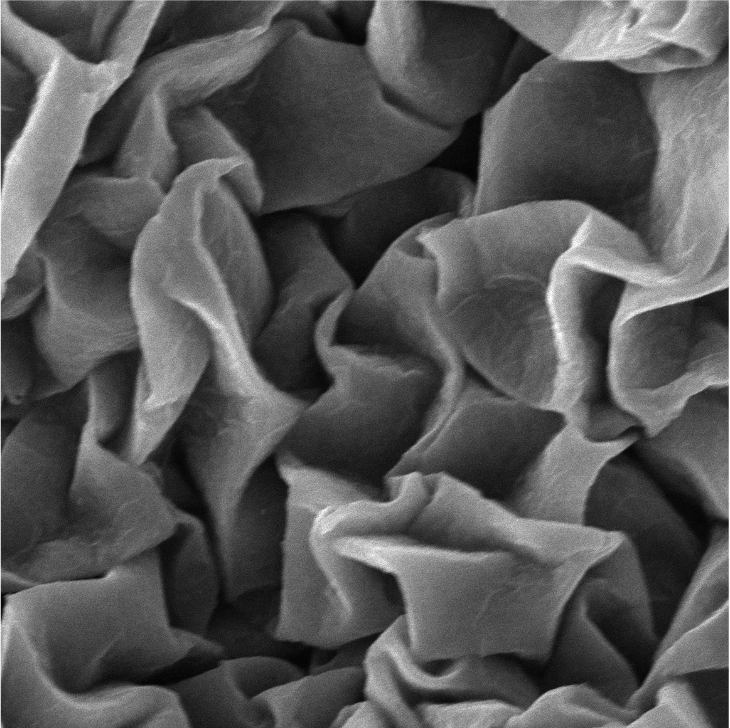

A nanomaterial called MXene which can be arranged in ultrathin layers is used to create the coating. The coating exhibits a unique crumpled structure with small peaks and valleys on its surface. These sharp peaks are very effective at killing common bacteria.

“Unlike other antibacterial methods that release substances to kill bacteria, our approach involves shaping the MXene surface in a specific way,” Min said. “This geometrically tuned surface possesses dynamic features that effectively prevent bacterial growth.”

One notable characteristic of this coating is its ability to stretch or reshape as needed. When deformed, it can eliminate over 99% of the bacteria adhered to its surface, leaving a clean and properly functioning area. The coating material remains effective against bacteria for extended periods and can be used with various implant types, enhancing its versatility.

Previously, scientists have explored various methods to modify the surfaces of medical devices and inhibit bacterial growth. However, most of these methods were expensive or complex to manufacture, rendering them unsuitable for large-scale production or practical medical use. In contrast, this new approach offers practicality and could enable large-scale production.

“This breakthrough holds great potential in revolutionizing the field of biomaterials and implantable devices, offering a promising avenue to enhance patient safety and prevent infections.”

Jouha MinAssistant Professor of Chemical Engineering

“The development of a novel surface modification strategy as a low-cost and scalable solution for long-term antibacterial protection is truly exciting,” Min said. “This breakthrough holds great potential in revolutionizing the field of biomaterials and implantable devices, offering a promising avenue to enhance patient safety and prevent infections.”

To validate the effectiveness of this approach, further studies utilizing animal models are planned. These studies will assess the clinical potential and suitability of this technology for real-life medical applications.

“This is an exciting direction for our future research,” Min said. “This work could help address a global human health threat and simplify the treatment of bacterial infections for patients with implants.”