$3.4M to turn up the heat at solar-thermal plants

Improved heat-trapping materials for solar thermal energy could help the U.S. meet its goal of cutting solar energy costs in half by 2030.

Improved heat-trapping materials for solar thermal energy could help the U.S. meet its goal of cutting solar energy costs in half by 2030.

To decarbonize industrial heat—a major contributor to global greenhouse gas emissions—and advance a form of solar power that’s cheaper to store, the Department of Energy is backing a transparent solar sponge with $3.1 million for further development by a University-of-Michigan-led team.

A second U-M project, to be funded with $300,000, will produce an open-source materials database as well as a suite of measurement tools enabling new materials to be assessed for solar thermal applications.

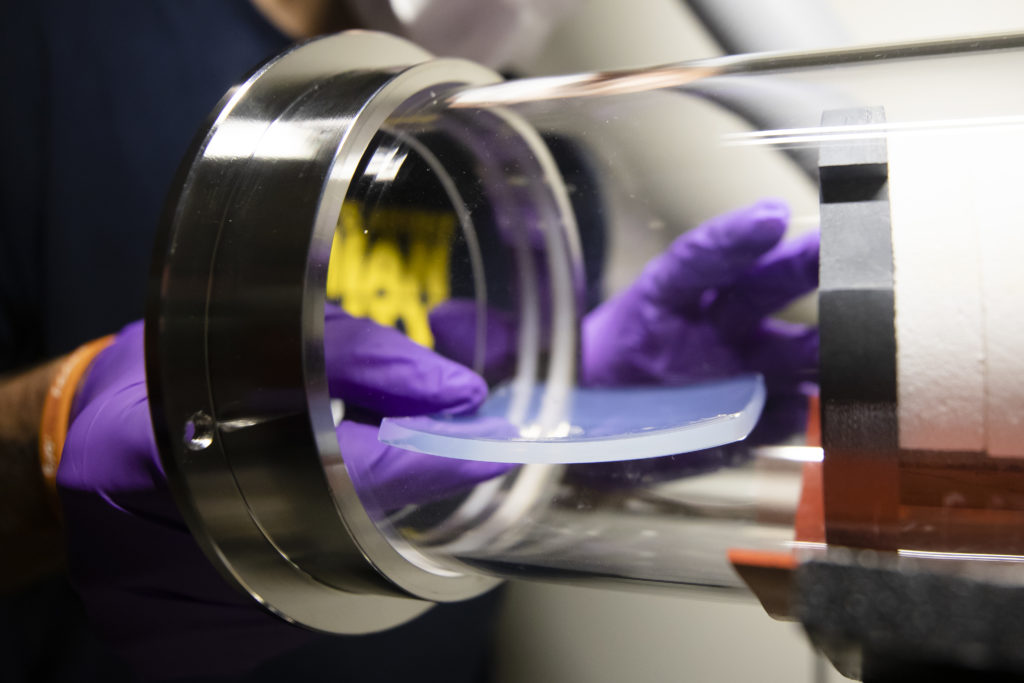

The solar sponge project will pilot a manufacturing strategy for a material that lets in sunlight while preventing heat from escaping.

“By trapping in more heat, our aerogel material would enable the use of efficient, high temperature power cycles, up to 700 degrees Celsius (1,300 Fahrenheit), within a plant that’s modular and easily deployed,” said Andrej Lenert, assistant professor of chemical engineering, who is leading the project.

Parabolic trough power plants, currently the most widely deployed solar thermal technology, use a sort of mirrored halfpipe to concentrate sunlight onto receiver tubes carrying a circulating fluid. That fluid absorbs heat and transports it for storage or use—generating electricity or producing fuels and other chemicals.

But current solar thermal plants rely on a thin coating on their receiver tubes to help heat the circulating fluid, typically water and steam, to 550 C (1,000 F). That is too low for many industrial heat applications, and conversion to electricity is not efficient enough to compete with more emissions-heavy power generators. And those coatings start to degrade at higher temperatures.

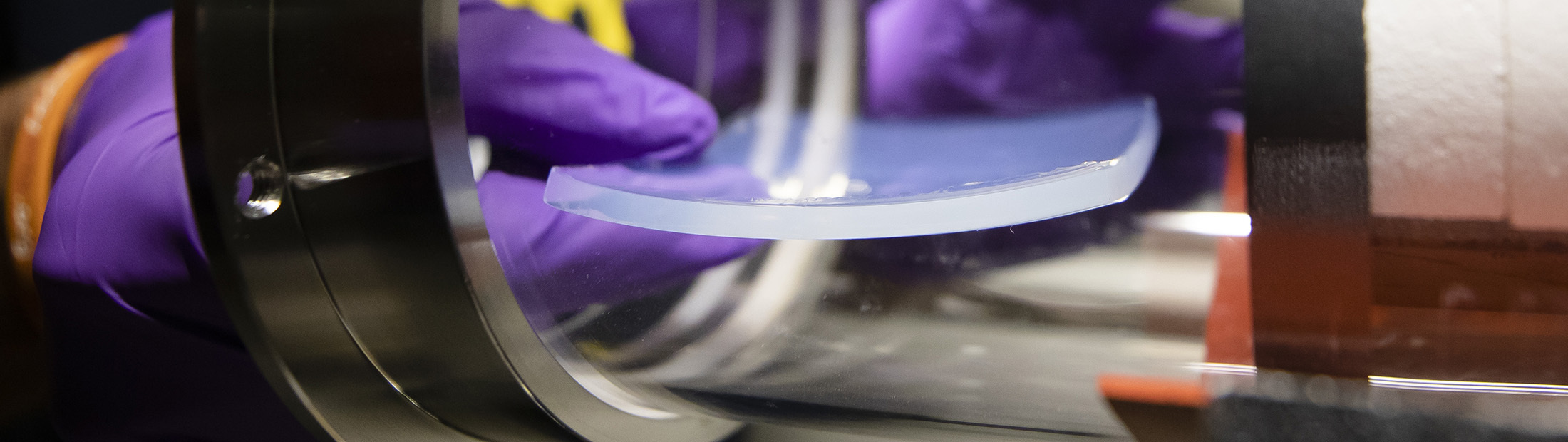

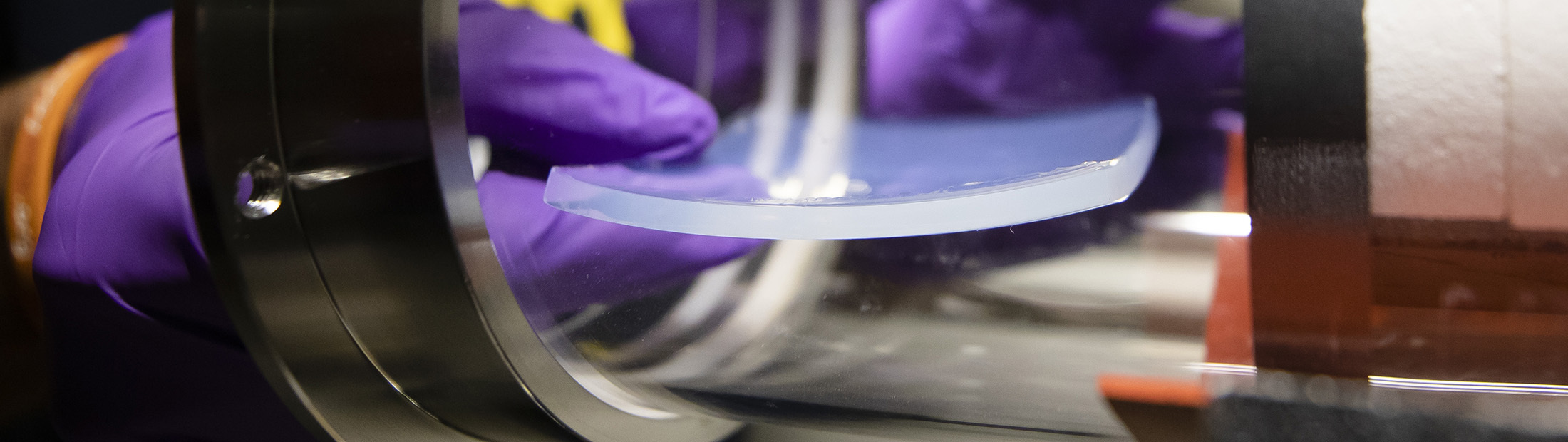

The team has designed their material to be more robust, enabling the use of more efficient circulating fluids that can reach the target temperatures. The funding will allow Lenert’s team to build a pilot-scale demonstration while simultaneously developing a manufacturing strategy.

“We’re borrowing concepts from the space shuttle program,” Lenert said. “Instead of making large monolithic, ceramic aerogels, which are prone to cracking, we’re trying to make them into smaller, tiled segments that are less likely to experience critical failure in the field.”

With this approach, the team plans to manufacture an array of their aerogel tiles for use in a four-meter long parabolic trough—the standard size for a single trough segment in today’s solar thermal plants. If successful, the approach should be easily scalable.

The team includes Neil Dasgupta, associate professor of mechanical engineering, who is responsible for the single-atom-thick surface modification of the aerogel that protects the material from degradation. Michael Thouless, the Janine Johnson Weins Professor of Engineering and a leading expert in fracture mechanics, will help ensure that the modified aerogel materials minimize the risk of cracking and other mechanical failures.

They are also collaborating with two commercial partners, AeroShield Materials and Forge Nano. AeroShield will help develop the process for making the aerogel tiles. Forge Nano will utilize their atomic layer deposition technology to apply the coatings at scale.

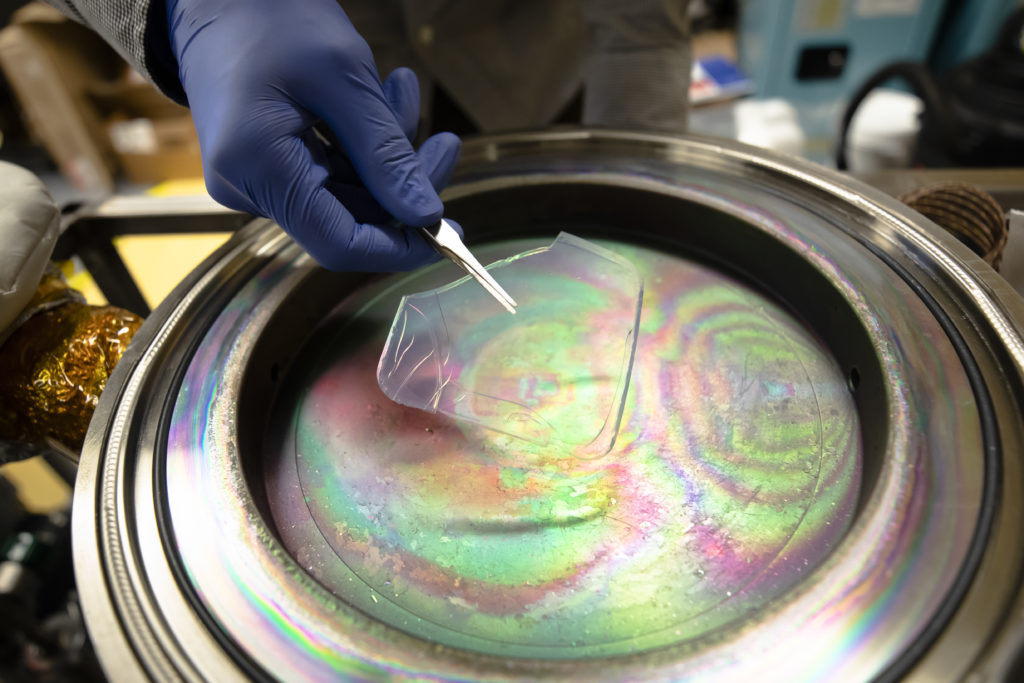

The second U-M project, funded with $300,000, will focus on measuring the high-temperature optical properties of materials used in solar thermal power applications, to see how well they let visible light in and prevent infrared waves from leaving.

Traditional optical measurements have focused on room-temperature properties, which don’t capture performance at high temperatures. The goal of the project is to develop tools and characterization approaches for determining temperature- and environment-dependent material properties—and ultimately develop an open-source database to collect and distribute the data.

“There really are no standardized techniques to do this,” said Rohini Bala Chandran, assistant professor of mechanical engineering at U-M leading the project. “And even the data that exists for these high-temperature radiative property measurements is sparse and unreliable because of inconsistencies in sample preparation, surface finish, thermal history and so on.”

As part of the 18-month project, Bala Chandran and her team have selected an initial group of ceramics, metals, coatings and other materials to begin their database. In collaboration with Sean Lubner, a research scientist from Lawrence Berkeley National Lab, the team will establish these standardized techniques to assess how these materials absorb, emit and reflect thermal radiation when subjected to temperatures up to about 1,000 C (1,800 F).

“We also hope this information will promote the discovery of new materials using a more data-driven approach,” said Bala Chandran. “Concentrated solar is never going to work unless you have a thermal storage solution, and that requires big improvements in our understanding of how these materials behave at higher temperatures.”

Thouless is also an Arthur F. Thurnau Professor and professor of mechanical engineering and materials science and engineering. Dasgupta is also an associate professor of materials science and engineering.